Automating Relay Quality Control

with Visual Inspection

About the Client

This article describes a real-life project. However, we cannot disclose our client’s name & the project details for privacy purposes.

In early 2022, a large-scale electronics manufacturer producing up to 100,000 relays per month faces critical challenges in its quality control process.

Even minor soldering defects — such as bridging, insufficient solder, or solder cracks — compromise relay functionality or reduce product lifespan. Worse, a single faulty relay often results in entire shipments being rejected. To minimize this risk, every relay has to be inspected manually under magnifying lenses, a process that is extremely labor-intensive, slow, and inconsistent.

Project Overview

The project focuses on developing an OCR-based system capable of automatically extracting personal information from ID documents.

Industry

IoT

Technology

Computer Vision, Image Processing, Edge Device Computing

Country

Vietnam

Timeline

Feb 2022 – Apr 2022

Challenges

The client’s manufacturing line is under significant pressure to maintain both output volume and reliability. However, several issues make this inc reasingly difficult:

High error risk

Soldering defects such as bridging, insufficient solder, and cracks occur frequently. These flaws are small but critical, as they cause malfunctions or reduce lifespan.

Severe quality penalties

A single defective relay can lead to the rejection of the entire lot, generating high costs and damaging trust with end customers.

Manual inspection bottlenecks

Every relay has to be visually inspected using magnifying lenses, requiring significant manpower. Inspectors often grow fatigued, leading to inconsistent results.

Scalability challenges

As production scales to 100,000 relays per month, relying on manual processes becomes unsustainable in terms of both cost and speed.

The manufacturer needs a reliable, automated inspection system that operates in real time, reduces reliance on manual checks, and consistently ensures product quality.

Solution

Rikkeisoft designs and delivers a computer vision–based Visual Inspection System, seamlessly integrated into the client’s relay production line

3D-printed mechanical structure with industrial cameras

A custom 3D-printed fixture houses six industrial cameras, enabling simultaneous image capture from all angles of relay solder joints. A dedicated lighting system is integrated to ensure optimal image quality and defect visibility.

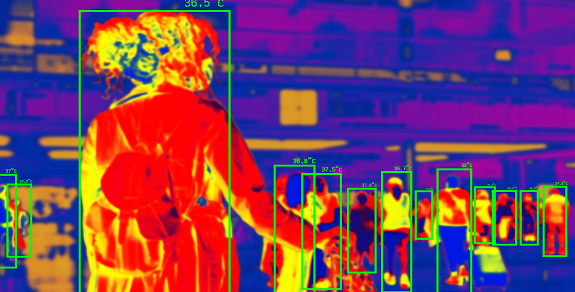

Real-time inline inspection

The system is directly integrated with the conveyor belt, enabling on-line inspection of relays during production without interrupting workflow. Processing speed is optimized to ≤0.5 seconds per unit, meeting real-time manufacturing requirements.

Advanced defect detection with image processing

Computer vision and image processing algorithms are applied to identify soldering issues such as bridging, cracks, and insufficient solder. Edge device computing ensures low latency and high efficiency on the factory floor.

Data logging for traceability

All inspection results and images are logged for future review, enabling traceability, quality audits, and process improvement insights.